Difference between revisions of "Gasket types, generic"

Jump to navigation

Jump to search

| (9 intermediate revisions by the same user not shown) | |||

| Line 15: | Line 15: | ||

! Commercial names | ! Commercial names | ||

|- | |- | ||

| − | | Ethylene propylene diene monomer (EPDM) | + | | Polyethylene foam |

| + | | 50-60 | ||

| + | | Strong, lightweight, closed cell. Available as sheets, strips or rods | ||

| + | | Excellent UV, ozone and chemical resistance. Water repellent | ||

| + | | | ||

| + | | Plastazote, Evasote, Climaloc, Magic Foamcord | ||

| + | |- | ||

| + | | [[Ethylene propylene diene]] monomer (EPDM) | ||

| 30-90 | | 30-90 | ||

| Excellent resistant to ultraviolet light, ozone, oxidants, heat, and compression set | | Excellent resistant to ultraviolet light, ozone, oxidants, heat, and compression set | ||

| Line 22: | Line 29: | ||

| | | | ||

|- | |- | ||

| − | | Ethylene | + | | [[Ethylene vinyl acetate]] closed-cell elastomeric seal (EVA) |

| | | | ||

| Closed cell foam that is lightweight, odorless with good flexibility and softness | | Closed cell foam that is lightweight, odorless with good flexibility and softness | ||

| Line 29: | Line 36: | ||

| | | | ||

|- | |- | ||

| − | | Fluorocarbon (FKM) | + | | [[Fluorocarbon]] (FKM) |

| 50-95 | | 50-95 | ||

| Excellent fluid resistance. Work well at low temperatures. | | Excellent fluid resistance. Work well at low temperatures. | ||

| Line 36: | Line 43: | ||

| Viton | | Viton | ||

|- | |- | ||

| − | | Isoprene (butyl rubber) | + | | [[Isoprene]] (butyl rubber) |

| 40-80 | | 40-80 | ||

| Excellent resistance to heat, oxygen and water. | | Excellent resistance to heat, oxygen and water. | ||

| Line 43: | Line 50: | ||

| | | | ||

|- | |- | ||

| − | | Nitrile rubber (NBR, Buna-N) | + | | [[Nitrile rubber]] (NBR, Buna-N) |

| 20-100 | | 20-100 | ||

| Good physical properties. Broad temperature range. | | Good physical properties. Broad temperature range. | ||

| Line 50: | Line 57: | ||

| | | | ||

|- | |- | ||

| − | | Polychloroprene | + | | [[Polychloroprene]] |

| 15-95 | | 15-95 | ||

| Good weathering, flame retardant. High tensile and tear strength | | Good weathering, flame retardant. High tensile and tear strength | ||

| Moderate chemicals and acids, ozone, oils fats, greases and many solvents. | | Moderate chemicals and acids, ozone, oils fats, greases and many solvents. | ||

| Strong oxidizing acids, esters, ketones, chlorinated, aromatic and nitro hydrocarbons | | Strong oxidizing acids, esters, ketones, chlorinated, aromatic and nitro hydrocarbons | ||

| − | | Neoprene | + | | [[Neoprene]] |

|- | |- | ||

| − | | Polytetrafluoroethylene (PTFE) | + | | [[Polytetrafluoroethylene]] (PTFE) |

| 73 | | 73 | ||

| Good electrical insulator. Inflammable and stable to light. Inert, often used in drug and food contact | | Good electrical insulator. Inflammable and stable to light. Inert, often used in drug and food contact | ||

| Hydrophobic and very resistant to all solvents, acids, and bases | | Hydrophobic and very resistant to all solvents, acids, and bases | ||

| Low strength and susceptible to creep at room temerpature. | | Low strength and susceptible to creep at room temerpature. | ||

| − | | Teflon | + | | [[Teflon]] |

|- | |- | ||

| − | | Silicone | + | | [[Silicone resin|Silicone rubber]] (dimethyl silicone) |

| 50-70 | | 50-70 | ||

| Most stable of all elastomers. Resistant to sunlight, oxygen and moisture. No odor or taste. | | Most stable of all elastomers. Resistant to sunlight, oxygen and moisture. No odor or taste. | ||

| Line 91: | Line 98: | ||

| | | | ||

| | | | ||

| + | |- | ||

| + | | Magnetic gaskets | ||

| + | | 79-80 | ||

| + | | A silicone rubber gasket filled with magnetite. Can be molded and extruded as needed | ||

| + | | | ||

| + | | | ||

| + | | Elastosil R781 (Wacker) | ||

|} | |} | ||

| + | |||

| + | |||

| + | [[Category:Materials database]][[Category:MWG]][[Category:Comparisons]][[Category:Gaskets]] | ||

Revision as of 10:22, 3 March 2023

Description

For further information, please see AIC wiki Gaskets for Exhibit Cases

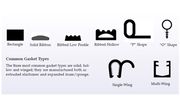

A compressible material used in an interface to reduce gaps and create tighter fitting joints. Gaskets are held under pressure to reduce leakage, transmission, and or vibration. As such, in museums, gaskets can be used to minimize air exchange between sealed cases and museums, to compensate for alignment irregularities between two edges, and to reduce potential for the transfer of dust, dirt, pollutants and pests. In the past, Natural rubber, Paper, Metal, Felt, Asbestos, and Cork were used for gaskets. More recently, synthetic options, called elastomers have become available.

Examples of some elastomers include:

| Material | Durometer Shore A (hardness) | General properties | Resistant to: | Attacked by: | Commercial names |

|---|---|---|---|---|---|

| Polyethylene foam | 50-60 | Strong, lightweight, closed cell. Available as sheets, strips or rods | Excellent UV, ozone and chemical resistance. Water repellent | Plastazote, Evasote, Climaloc, Magic Foamcord | |

| Ethylene propylene diene monomer (EPDM) | 30-90 | Excellent resistant to ultraviolet light, ozone, oxidants, heat, and compression set | Resists the swelling effects of polar chemicals, animal and vegetable oils. | Mineral oils and solvents, aromatic hydrocarbons | |

| Ethylene vinyl acetate closed-cell elastomeric seal (EVA) | Closed cell foam that is lightweight, odorless with good flexibility and softness | Excellent ozone, chemical resistance. Good acoustic properties | low resistance to heat and solvents | ||

| Fluorocarbon (FKM) | 50-95 | Excellent fluid resistance. Work well at low temperatures. | Very good chemical resistance to acids and oils as well as hydrocarbon and halogenated solvents | Ketones, low molecular weight esters and nitro-containing hydrocarbons. | Viton |

| Isoprene (butyl rubber) | 40-80 | Excellent resistance to heat, oxygen and water. | Low gas permeation. High vibration absoprtion (dampening) | Hydrocarbons solvents and oils | |

| Nitrile rubber (NBR, Buna-N) | 20-100 | Good physical properties. Broad temperature range. | Resistant to water, petroleums and oils | ||

| Polychloroprene | 15-95 | Good weathering, flame retardant. High tensile and tear strength | Moderate chemicals and acids, ozone, oils fats, greases and many solvents. | Strong oxidizing acids, esters, ketones, chlorinated, aromatic and nitro hydrocarbons | Neoprene |

| Polytetrafluoroethylene (PTFE) | 73 | Good electrical insulator. Inflammable and stable to light. Inert, often used in drug and food contact | Hydrophobic and very resistant to all solvents, acids, and bases | Low strength and susceptible to creep at room temerpature. | Teflon |

| Silicone rubber (dimethyl silicone) | 50-70 | Most stable of all elastomers. Resistant to sunlight, oxygen and moisture. No odor or taste. | Resistant to high and low temperature ranges, fatigue, most chemicals, oils, oxygen, and ozone | Poor resistance to aromatic solvents. May have residual silicone oil that creeps to other surfaces. | |

| Styrene butadiene (SBR, Buna-S) | 40-100 | Low cost, general purpose elastomer. Excellent flex and strength | Resistant to alcohols and ketones | Petroleum based fluids | |

| Aramid | |||||

| Cellular silicone sponge (poly-dimethyl siloxane also referred to as PDMS) | silicone rubber that has been foamed into a uniform unicellular structure. It has the same characteristics as silicone rubber and is shaped by either extrusion or cutting. | ||||

| Magnetic gaskets | 79-80 | A silicone rubber gasket filled with magnetite. Can be molded and extruded as needed | Elastosil R781 (Wacker) |