Difference between revisions of "Synthetic fiber"

Jump to navigation

Jump to search

(username removed) |

|||

| (11 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| + | [[File:MFA199837 Synthetic fiber.jpg|thumb|Synthetic fibers dress<br>MFA# 1998.37]] | ||

| + | == Description == | ||

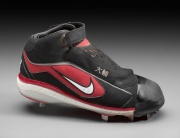

[[File:L-R 27.2008-SC191839.jpg|thumb|'''MFA Acc. #:''' L-R 27.2008]] | [[File:L-R 27.2008-SC191839.jpg|thumb|'''MFA Acc. #:''' L-R 27.2008]] | ||

| − | + | Fibers manufactured from substances that have been produced or modified by chemical reactions. Artificial fibers were first made in 1842 when molten glass was formed into filaments. By the late 1880s, man-made fabrics were being made from [[cellulose%20nitrate|Cellulose nitrate]] and [[rayon%20fiber|Rayon]] fibers. Current examples include: [[acetate%20fiber|Acetate]], [[acrylic%20fiber|Acrylic]], [[alginic%20fiber|Alginic]], [[anidex%20fiber|Anidex]], [[aramid%20fiber|Aramid]], [[azlon%20fiber|Azlon]], [[casein%20fiber|Casein]], [[cupro%20fiber|Cupro]], [[nylon%20fiber|Nylon]], [[novoloid%20fiber|Novoloid]], [[nytril%20fiber|Nytril]], [[modacrylic%20fiber|Modacrylic]], [[modal%20fiber|Modal]], [[olefin%20fiber|Olefin]], [[polyester%20fiber|Polyester]], [[Polyethylene fiber|Polyethylene]], [[Polypropylene fiber|Polypropylene]], [[saran%20fiber|Saran]], [[spandex%20fiber|Spandex]], [[sulfar|Sulfar]], [[triacetate%20fiber|Triacetate]], [[vinal%20fiber|Vinal]], and [[vinyon%20fiber|Vinyon]]. | |

| − | + | [[File:L-SE 1071.5.1-SC192047.jpg|thumb|'''MFA Acc. #:''' L-SE 1071.5.1]] | |

| − | Fibers manufactured from substances that have been produced or modified by chemical reactions. Artificial fibers were first made in 1842 when molten glass was formed into filaments. By the late 1880s, man-made fabrics were being made from [ | ||

| − | + | ==Properties of Synthetic Fibers (Part 1)== | |

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Fiber | ||

| + | ! Composition | ||

| + | ! Development date | ||

| + | ! Common trade name | ||

| + | ! colspan="2" | Density | ||

| + | ! Denier (g/9000m) | ||

| + | ! Tenacity (g/denier) | ||

| + | ! colspan="2" | Elongation at break (%) | ||

| + | ! Initial modulus | ||

| + | ! Moisture<br /> regain (%) | ||

| + | |- | ||

| + | | acetate | ||

| + | | cellulose triacetate | ||

| + | | 1919 | ||

| + | | Celanese; Arnel;<br /> Tenite | ||

| + | | colspan="2" | 1.25-1.35 | ||

| + | | | ||

| + | | 1.1-1.4<br /> (dry); 0.65-<br /> 0.75 wet) | ||

| + | | colspan="2" | 25-35 (dry);<br /> 35-45 (wet) | ||

| + | | 35-40 | ||

| + | | 6.5 | ||

| + | |- | ||

| + | | acrylic | ||

| + | | >85% acrylonitrile | ||

| + | | 1950 | ||

| + | | Acrilan, Creslan, Courtelle, Orlon | ||

| + | | colspan="2" | 1.16-1.18 | ||

| + | | 2-8 | ||

| + | | 2-3.6 (dry) | ||

| + | | colspan="2" | 20-55 | ||

| + | | 25-63 | ||

| + | | 1.0-3.0 | ||

| + | |- | ||

| + | | aramid (meta) | ||

| + | | poly-m-phenylene terephthalamide | ||

| + | | | ||

| + | | Nomex, Conex | ||

| + | | colspan="2" | 1.38 | ||

| + | | 2-5 | ||

| + | | 3-6 | ||

| + | | colspan="2" | 2-30 | ||

| + | | 130-150 | ||

| + | | 3.5 | ||

| + | |- | ||

| + | | aramid (para) | ||

| + | | poly-p-phenylene terephthalamide | ||

| + | | 1965 | ||

| + | | Kevlar | ||

| + | | colspan="2" | 1.44 | ||

| + | | 1.0-1.5 | ||

| + | | 25-30 | ||

| + | | colspan="2" | 3-6 | ||

| + | | 500-<br /> 1000 | ||

| + | | 7.0 | ||

| + | |- | ||

| + | | azlon | ||

| + | | protein | ||

| + | | 1930s | ||

| + | | Aralac, Ardil, Lanital | ||

| + | | colspan="2" | 1.25-1.3 | ||

| + | | | ||

| + | | 0.9-1.1<br /> (dry); 0.3-<br /> 0.6 (wet) | ||

| + | | colspan="2" | 60-70 | ||

| + | | | ||

| + | | 14 | ||

| + | |- | ||

| + | | modacrylic | ||

| + | | 35-85% acrylonitrile | ||

| + | | 1949 | ||

| + | | Dynel; Verel, SEF | ||

| + | | colspan="2" | 1.35-1.37 | ||

| + | | 2-8 | ||

| + | | 1.8-2.5<br /> (dry); 1.7-<br /> 2.4 (wet) | ||

| + | | colspan="2" | 35-48 | ||

| + | | 25-56 | ||

| + | | 0.4-4.0 | ||

| + | |- | ||

| + | | nylon 6 | ||

| + | | polycaprolactam | ||

| + | | 1939 | ||

| + | | Perlon; Kapron, Power silk | ||

| + | | colspan="2" | 1.14 | ||

| + | | 1.5-5 | ||

| + | | 3.8-8.3<br /> (dry); 3.5-<br /> 7.1 (wet) | ||

| + | | colspan="2" | 16-50 (dry);<br /> 19-55 (wet) | ||

| + | | 25-35 | ||

| + | | 3.5-5.0 | ||

| + | |- | ||

| + | | nylon 6,6 | ||

| + | | polyhexamethylene adipamide | ||

| + | | 1935 | ||

| + | | Fiber 66; Antron; Stainmaster | ||

| + | | colspan="2" | 1.14 | ||

| + | | 1.5-5 | ||

| + | | 4.6-9.0<br /> (dry); 4.0-<br /> 7.7 (wet) | ||

| + | | colspan="2" | 19-40%<br /> (dry); 32-<br /> 46% (wet) | ||

| + | | 33-46 | ||

| + | | 3.8-4.5 | ||

| + | |- | ||

| + | | nytril | ||

| + | | >85% vinylidene dintrile | ||

| + | | 1955;<br /> discontinued in 1970s | ||

| + | | Darvan | ||

| + | | colspan="2" | 1.18 | ||

| + | | | ||

| + | | 2.0 (dry);<br /> 1.7 (wet) | ||

| + | | colspan="2" | 30 | ||

| + | | | ||

| + | | 2-3 | ||

| + | |- | ||

| + | | polyester | ||

| + | | polyester terephthalate | ||

| + | | 1941 | ||

| + | | Dacron, Terylene; Hollytex | ||

| + | | colspan="2" | | ||

| + | | 1.5-5 | ||

| + | | 2.2-9.5 | ||

| + | | colspan="2" | 10-50 | ||

| + | | 25-50 | ||

| + | | 0.1-0.4 | ||

| + | |- | ||

| + | | polyethylene | ||

| + | | high density polyethylene | ||

| + | | 1954 | ||

| + | | Tyvek; Reevon | ||

| + | | colspan="2" | 0.95-0.96 | ||

| + | | 2-10 | ||

| + | | 5.0-8.0 | ||

| + | | colspan="2" | 14-20 | ||

| + | | | ||

| + | | <0.1 | ||

| + | |- | ||

| + | | polypropylene | ||

| + | | polypropylene | ||

| + | | 1957 | ||

| + | | Herculon, Marvess | ||

| + | | colspan="2" | 0.85-0.94 | ||

| + | | 2-10 | ||

| + | | 3.5-9.0 | ||

| + | | colspan="2" | 15-35 | ||

| + | | 29-45 | ||

| + | | <0.1 | ||

| + | |- | ||

| + | | polyurethane | ||

| + | | >85%polyurethane | ||

| + | | 1958 | ||

| + | | spandex, Lycra | ||

| + | | colspan="2" | 1.20-1.25 | ||

| + | | 2.5-20 | ||

| + | | 0.5-1.5 | ||

| + | | colspan="2" | 500-700 | ||

| + | | | ||

| + | | 0.3-1.2 | ||

| + | |- | ||

| + | | polyvinyl chloride | ||

| + | | >85% vinyl chloride units | ||

| + | | | ||

| + | | vinyon;<br /> Evilon, Thermovyl | ||

| + | | colspan="2" | 1.38-1.40 | ||

| + | | | ||

| + | | 2.7-3.0 (wet<br /> or dry) | ||

| + | | colspan="2" | 12-20 | ||

| + | | | ||

| + | | 0 | ||

| + | |- | ||

| + | | rayon (cupro) | ||

| + | | regenerated cellulose | ||

| + | | 1890 | ||

| + | | Cuprama; Cupresa | ||

| + | | colspan="2" | 1.54 | ||

| + | | 2-3 | ||

| + | | 1.7-2.3<br /> (dry); 1.1-<br /> 1.135 (wet) | ||

| + | | colspan="2" | 10-17 (dry);<br /> 17-23 (wet) | ||

| + | | | ||

| + | | 11-12.5 | ||

| + | |- | ||

| + | | rayon (viscose) | ||

| + | | regenerated cellulose | ||

| + | | 1892 | ||

| + | | Avtex | ||

| + | | colspan="2" | 1.46-1.54 | ||

| + | | 2-3 | ||

| + | | 2.0-2.6<br /> (wdry); 1.0-<br /> 1.5 (wet) | ||

| + | | colspan="2" | 13-15 (dry);<br /> 20-40 (wet) | ||

| + | | | ||

| + | | 11-16.6 | ||

| + | |- | ||

| + | | vinal | ||

| + | | >50% vinyl alcohol units | ||

| + | | 1924 | ||

| + | | Synthofil; Vinylon | ||

| + | | colspan="2" | 1.26-1.30 | ||

| + | | | ||

| + | | 3.0 -8.5<br /> (dry); 3.2-<br /> 7.6 (wet) | ||

| + | | colspan="2" | 9-26 (dry);<br /> 10-27 (wet) | ||

| + | | | ||

| + | | 3.0-9.0 | ||

| + | |} | ||

| + | ==Properties of Synthetic Fibers (Part 2)== | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Fiber | ||

| + | ! colspan="2" | Degradation | ||

| + | ! colspan="2" | Dyes used | ||

| + | ! colspan="3" | Microscopic characteristics | ||

| + | ! colspan="3" | Applications | ||

| + | |- | ||

| + | | acetate | ||

| + | | colspan="2" | Degrades in acids and concentrated alkalis | ||

| + | | colspan="2" | disperse | ||

| + | | colspan="3" | irregular cross section with multiple lobes; lengthwise striations | ||

| + | | colspan="3" | coats, suits, linings, cigarette filters | ||

| + | |- | ||

| + | | acrylic | ||

| + | | colspan="2" | Susceptible to heat; accumulates static charge | ||

| + | | colspan="2" | basic, disperse, pigment | ||

| + | | colspan="3" | variable cross section | ||

| + | | colspan="3" | subsitute for wool in coats, sweaters, hosiery, blankets, filters | ||

| + | |- | ||

| + | | aramid (meta) | ||

| + | | colspan="2" | Degraded by acids, alkalis, oxidizing agents and UV light | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | fiber is smooth; cross section is dogbone | ||

| + | | colspan="3" | filter bags for hot stack gases, flame-resistant clothing | ||

| + | |- | ||

| + | | aramid (para) | ||

| + | | colspan="2" | Degraded by acids, alkalis, oxidizing agents and UV light | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | fiber is smooth, cross section is circular | ||

| + | | colspan="3" | radial tires belts, bulletproof vests, resin reinforcements | ||

| + | |- | ||

| + | | azlon | ||

| + | | colspan="2" | Degraded by alkalis; weak when wet; susceptible to microbiological growths | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | diameter=20-30 microns, cross section is circular or bean-shaped, filament is smooth | ||

| + | | colspan="3" | silk substitute | ||

| + | |- | ||

| + | | modacrylic | ||

| + | | colspan="2" | Resistant to alkalis and acids | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | | ||

| + | | colspan="3" | flame-resistant clothing, artificial fur, children's sleepwear, tents | ||

| + | |- | ||

| + | | nylon 6 | ||

| + | | colspan="2" | Degraded by concentrated acids and phenol; resistant to alkalis and most organic solvents | ||

| + | | colspan="2" | acid, disperse, mordant, pigment, reactive | ||

| + | | colspan="3" | fiber is smooth, cross section is circular | ||

| + | | colspan="3" | hosiery, lingerie, sports garments, upholstery | ||

| + | |- | ||

| + | | nylon 6,6 | ||

| + | | colspan="2" | Degraded by concentrated acids and phenol; resistant to alkalis and most organic solvents | ||

| + | | colspan="2" | acid, disperse, mordant, pigment, reactive | ||

| + | | colspan="3" | fiber is smooth, cross section is circular or trilobal | ||

| + | | colspan="3" | tires, ropes, seat belts, parachutes, fishing lines and nets; surgical sutures; brushes | ||

| + | |- | ||

| + | | nytril | ||

| + | | colspan="2" | Resistant to sunlight, oxidation and insects. | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | opaque, white with flattened or hook-shaped cross section | ||

| + | | colspan="3" | sweaters, pile fabrics, in wool blends | ||

| + | |- | ||

| + | | polyester | ||

| + | | colspan="2" | Degrades in strong acids, strong alkalis and creson. | ||

| + | | colspan="2" | disperse, pigment | ||

| + | | colspan="3" | smooth fibers; cross section may be circular, trilobal or polygon | ||

| + | | colspan="3" | permanent press clothing, fiberfill, carpets, sewing thread, seat belts, yarns, nonwoven fabrics | ||

| + | |- | ||

| + | | polyethylene | ||

| + | | colspan="2" | Resistant to acids, alkalis and bleaches; dissolves in dry-cleaning solvents, degrades slowly in sunlight | ||

| + | | colspan="2" | basic, disperse pigments | ||

| + | | colspan="3" | cross section is circular or elliptical | ||

| + | | colspan="3" | cordage, webbing; upholstery, outdoor applications | ||

| + | |- | ||

| + | | polypropylene | ||

| + | | colspan="2" | Resistant to strong acids and alkalis; resistant to biodeterioration | ||

| + | | colspan="2" | basic, disperse pigments | ||

| + | | colspan="3" | cross section is circular or elliptical | ||

| + | | colspan="3" | upholstery, carpets, ropes, nets, disposable nonwoven fabrics | ||

| + | |- | ||

| + | | polyurethane | ||

| + | | colspan="2" | Chlorine causes slow degradation | ||

| + | | colspan="2" | acid, disperse, reactive, vat | ||

| + | | colspan="3" | | ||

| + | | colspan="3" | elastomeric fabrics; swimwere; althletic clothes | ||

| + | |- | ||

| + | | polyvinyl chloride | ||

| + | | colspan="2" | Soluble in chlorinated and aromatic solvents; degrades with heat and light | ||

| + | | colspan="2" | basic,<br /> disperse, pigment | ||

| + | | colspan="3" | irregular cross section | ||

| + | | colspan="3" | elastomeric fabrics; outdoor fabrics (tents, awnings, rain gear etc) | ||

| + | |- | ||

| + | | rayon (cupro) | ||

| + | | colspan="2" | Degrades in strong alkalis, acids and undiluted bleaches. Resistant to dry cleaning solvents | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | circular cross section with no striations | ||

| + | | colspan="3" | sheer fabrics and netting; lightbulb filaments | ||

| + | |- | ||

| + | | rayon (viscose) | ||

| + | | colspan="2" | Degrades in strong alkalis, acids and undiluted bleaches. Resistant to dry cleaning solvents | ||

| + | | colspan="2" | direct | ||

| + | | colspan="3" | lengthwise striations; early samples have circular cross sections with serrations, later samples may be dog-boned or trilobal | ||

| + | | colspan="3" | rugs, cotton substitute, nonwoven fabrics, paper (cellophane) | ||

| + | |- | ||

| + | | vinal | ||

| + | | colspan="2" | Resistant to microorganisms, insects, and most chemicals. | ||

| + | | colspan="2" | | ||

| + | | colspan="3" | fibers are smooth; cross section is round, ben-shaped or u-shaped | ||

| + | | colspan="3" | raincoats, jackets, umbrellas, tarps, fishnets, awnings. | ||

| + | |} | ||

| + | ==Fiber Burn Tests== | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ! Fiber | ||

| + | ! Appearance | ||

| + | ! Odor | ||

| + | ! Residue | ||

| + | |- | ||

| + | | colspan="4" | Natural fibers | ||

| + | |- | ||

| + | | Cotton | ||

| + | | Burns very fast with a bright yellow flame, similar to paper | ||

| + | | burnt paper | ||

| + | | burnt ends look bushy | ||

| + | |- | ||

| + | | Linen | ||

| + | | Burns very fast with a bright yellow flame, similar to paper | ||

| + | | burnt paper | ||

| + | | burnt ends appear melted together | ||

| + | |- | ||

| + | | Silk | ||

| + | | Burns and bubbles faster than wool with a yellow flame | ||

| + | | burnt hair (mild) | ||

| + | | black, brittle, spherical beads | ||

| + | |- | ||

| + | | Weighted silk | ||

| + | | Does not burn; the fabric will char | ||

| + | | burnt hair (faint) | ||

| + | | fabric retains shape | ||

| + | |- | ||

| + | | Wool | ||

| + | | Burns slowly; bubbles while burning; easy to put out flame | ||

| + | | burnt hair (strong) | ||

| + | | black, brittle, irregular beads | ||

| + | |- | ||

| + | | colspan="4" | Synthetic fibers | ||

| + | |- | ||

| + | | Acrylic | ||

| + | | Burns readily with smoky flame | ||

| + | | acidic | ||

| + | | hard ash | ||

| + | |- | ||

| + | | Aramid | ||

| + | | Does not burn | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | Cellulose acetate | ||

| + | | Burns fast with a yellow flame; may melt and sputter | ||

| + | | burnt paper | ||

| + | | hard, black beads; similar to silk | ||

| + | |- | ||

| + | | Modacrylic | ||

| + | | Self-extinguishing | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | Nylon | ||

| + | | Melts first, then ignites and burns rapidly. | ||

| + | | burnt plastic | ||

| + | | | ||

| + | |- | ||

| + | | Polyester | ||

| + | | Difficult to ignite, self-extinguishing. Burns with shiny, yellow-orange, sooty flame. | ||

| + | | sweet | ||

| + | | hard ash | ||

| + | |- | ||

| + | | Polyethylene | ||

| + | | Burns with a heavy, sooty, waxy smoke. Softens at 120 C. | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | Polypropylene | ||

| + | | Burns with a heavy, sooty, waxy smoke. | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | Polyurethane | ||

| + | | Burns with bright flame and minimal smoke | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | | Polyvinyl chloride | ||

| + | | Burns with green smoky flame, self- extinguishing. | ||

| + | | acidic; releases hydrochloric acid | ||

| + | | | ||

| + | |- | ||

| + | | Rayon (regenerated cellulose) | ||

| + | | Burns very fast with a bright yellow flame, similar to paper | ||

| + | | burnt paper | ||

| + | | light, white ash | ||

| + | |- | ||

| + | | Vinal | ||

| + | | Does not burn | ||

| + | | | ||

| + | | | ||

| + | |} | ||

== Synonyms and Related Terms == | == Synonyms and Related Terms == | ||

| − | synthetic fibers; man-made fiber; manmade fiber; man-made fibre; fibras | + | synthetic fibers; man-made fiber; manmade fiber; man-made fibre; fibras sintéticas(Esp.) |

| − | == | + | == For easy printing and to download == |

[[media:download_file_43.pdf|Properties of Synthetic Fibers]] | [[media:download_file_43.pdf|Properties of Synthetic Fibers]] | ||

| Line 15: | Line 424: | ||

[[media:download_file_390.pdf|Fiber Burn Tests]] | [[media:download_file_390.pdf|Fiber Burn Tests]] | ||

| + | == Resources and Citations == | ||

| + | * Wikipedia: [https://en.wikipedia.org/wiki/Synthetic_fiber Synthetic fiber] Accessed Oct. 2024 | ||

| + | * Hoechst Celanese Corporation, ''Dictionary of Fiber & Textile Technology'' (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990 | ||

| + | * Rosalie Rosso King, ''Textile Identification, Conservation, and Preservation'', Noyes Publications, Park Ridge, NJ, 1985 | ||

| + | * Marjory L. Joseph, ''Introductory Textile Science'', Holt, Rinehart and Winston, Fort Worth, TX, 1986 | ||

| + | * J.Gordon Cook, ''Handbook of Textile Fibres:II Man-made Fibres'', Merrow Publishing Co. , Durham, England | ||

| + | * Theodore J. Reinhart, 'Glossary of Terms', ''Engineered Plastics'', ASM International, 1988 | ||

| + | * Art and Architecture Thesaurus Online, https://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000 | ||

| + | * ''Fairchild's Dictionary of Textiles'', Phyllis G.Tortora, Robert S. Merkel (eds.), Fairchild Publications, New York City, 7th edition, 1996 | ||

| − | + | [[Category:Materials database]][[Category:MWG]][[Category:Comparisons]][[Category: Sheet, Fabric]] | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | [[Category:Materials database]] | ||

Latest revision as of 14:24, 14 October 2024

Description

Fibers manufactured from substances that have been produced or modified by chemical reactions. Artificial fibers were first made in 1842 when molten glass was formed into filaments. By the late 1880s, man-made fabrics were being made from Cellulose nitrate and Rayon fibers. Current examples include: Acetate, Acrylic, Alginic, Anidex, Aramid, Azlon, Casein, Cupro, Nylon, Novoloid, Nytril, Modacrylic, Modal, Olefin, Polyester, Polyethylene, Polypropylene, Saran, Spandex, Sulfar, Triacetate, Vinal, and Vinyon.

Properties of Synthetic Fibers (Part 1)

| Fiber | Composition | Development date | Common trade name | Density | Denier (g/9000m) | Tenacity (g/denier) | Elongation at break (%) | Initial modulus | Moisture regain (%) | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| acetate | cellulose triacetate | 1919 | Celanese; Arnel; Tenite |

1.25-1.35 | 1.1-1.4 (dry); 0.65- 0.75 wet) |

25-35 (dry); 35-45 (wet) |

35-40 | 6.5 | |||

| acrylic | >85% acrylonitrile | 1950 | Acrilan, Creslan, Courtelle, Orlon | 1.16-1.18 | 2-8 | 2-3.6 (dry) | 20-55 | 25-63 | 1.0-3.0 | ||

| aramid (meta) | poly-m-phenylene terephthalamide | Nomex, Conex | 1.38 | 2-5 | 3-6 | 2-30 | 130-150 | 3.5 | |||

| aramid (para) | poly-p-phenylene terephthalamide | 1965 | Kevlar | 1.44 | 1.0-1.5 | 25-30 | 3-6 | 500- 1000 |

7.0 | ||

| azlon | protein | 1930s | Aralac, Ardil, Lanital | 1.25-1.3 | 0.9-1.1 (dry); 0.3- 0.6 (wet) |

60-70 | 14 | ||||

| modacrylic | 35-85% acrylonitrile | 1949 | Dynel; Verel, SEF | 1.35-1.37 | 2-8 | 1.8-2.5 (dry); 1.7- 2.4 (wet) |

35-48 | 25-56 | 0.4-4.0 | ||

| nylon 6 | polycaprolactam | 1939 | Perlon; Kapron, Power silk | 1.14 | 1.5-5 | 3.8-8.3 (dry); 3.5- 7.1 (wet) |

16-50 (dry); 19-55 (wet) |

25-35 | 3.5-5.0 | ||

| nylon 6,6 | polyhexamethylene adipamide | 1935 | Fiber 66; Antron; Stainmaster | 1.14 | 1.5-5 | 4.6-9.0 (dry); 4.0- 7.7 (wet) |

19-40% (dry); 32- 46% (wet) |

33-46 | 3.8-4.5 | ||

| nytril | >85% vinylidene dintrile | 1955; discontinued in 1970s |

Darvan | 1.18 | 2.0 (dry); 1.7 (wet) |

30 | 2-3 | ||||

| polyester | polyester terephthalate | 1941 | Dacron, Terylene; Hollytex | 1.5-5 | 2.2-9.5 | 10-50 | 25-50 | 0.1-0.4 | |||

| polyethylene | high density polyethylene | 1954 | Tyvek; Reevon | 0.95-0.96 | 2-10 | 5.0-8.0 | 14-20 | <0.1 | |||

| polypropylene | polypropylene | 1957 | Herculon, Marvess | 0.85-0.94 | 2-10 | 3.5-9.0 | 15-35 | 29-45 | <0.1 | ||

| polyurethane | >85%polyurethane | 1958 | spandex, Lycra | 1.20-1.25 | 2.5-20 | 0.5-1.5 | 500-700 | 0.3-1.2 | |||

| polyvinyl chloride | >85% vinyl chloride units | vinyon; Evilon, Thermovyl |

1.38-1.40 | 2.7-3.0 (wet or dry) |

12-20 | 0 | |||||

| rayon (cupro) | regenerated cellulose | 1890 | Cuprama; Cupresa | 1.54 | 2-3 | 1.7-2.3 (dry); 1.1- 1.135 (wet) |

10-17 (dry); 17-23 (wet) |

11-12.5 | |||

| rayon (viscose) | regenerated cellulose | 1892 | Avtex | 1.46-1.54 | 2-3 | 2.0-2.6 (wdry); 1.0- 1.5 (wet) |

13-15 (dry); 20-40 (wet) |

11-16.6 | |||

| vinal | >50% vinyl alcohol units | 1924 | Synthofil; Vinylon | 1.26-1.30 | 3.0 -8.5 (dry); 3.2- 7.6 (wet) |

9-26 (dry); 10-27 (wet) |

3.0-9.0 | ||||

Properties of Synthetic Fibers (Part 2)

| Fiber | Degradation | Dyes used | Microscopic characteristics | Applications | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| acetate | Degrades in acids and concentrated alkalis | disperse | irregular cross section with multiple lobes; lengthwise striations | coats, suits, linings, cigarette filters | ||||||

| acrylic | Susceptible to heat; accumulates static charge | basic, disperse, pigment | variable cross section | subsitute for wool in coats, sweaters, hosiery, blankets, filters | ||||||

| aramid (meta) | Degraded by acids, alkalis, oxidizing agents and UV light | fiber is smooth; cross section is dogbone | filter bags for hot stack gases, flame-resistant clothing | |||||||

| aramid (para) | Degraded by acids, alkalis, oxidizing agents and UV light | fiber is smooth, cross section is circular | radial tires belts, bulletproof vests, resin reinforcements | |||||||

| azlon | Degraded by alkalis; weak when wet; susceptible to microbiological growths | diameter=20-30 microns, cross section is circular or bean-shaped, filament is smooth | silk substitute | |||||||

| modacrylic | Resistant to alkalis and acids | flame-resistant clothing, artificial fur, children's sleepwear, tents | ||||||||

| nylon 6 | Degraded by concentrated acids and phenol; resistant to alkalis and most organic solvents | acid, disperse, mordant, pigment, reactive | fiber is smooth, cross section is circular | hosiery, lingerie, sports garments, upholstery | ||||||

| nylon 6,6 | Degraded by concentrated acids and phenol; resistant to alkalis and most organic solvents | acid, disperse, mordant, pigment, reactive | fiber is smooth, cross section is circular or trilobal | tires, ropes, seat belts, parachutes, fishing lines and nets; surgical sutures; brushes | ||||||

| nytril | Resistant to sunlight, oxidation and insects. | opaque, white with flattened or hook-shaped cross section | sweaters, pile fabrics, in wool blends | |||||||

| polyester | Degrades in strong acids, strong alkalis and creson. | disperse, pigment | smooth fibers; cross section may be circular, trilobal or polygon | permanent press clothing, fiberfill, carpets, sewing thread, seat belts, yarns, nonwoven fabrics | ||||||

| polyethylene | Resistant to acids, alkalis and bleaches; dissolves in dry-cleaning solvents, degrades slowly in sunlight | basic, disperse pigments | cross section is circular or elliptical | cordage, webbing; upholstery, outdoor applications | ||||||

| polypropylene | Resistant to strong acids and alkalis; resistant to biodeterioration | basic, disperse pigments | cross section is circular or elliptical | upholstery, carpets, ropes, nets, disposable nonwoven fabrics | ||||||

| polyurethane | Chlorine causes slow degradation | acid, disperse, reactive, vat | elastomeric fabrics; swimwere; althletic clothes | |||||||

| polyvinyl chloride | Soluble in chlorinated and aromatic solvents; degrades with heat and light | basic, disperse, pigment |

irregular cross section | elastomeric fabrics; outdoor fabrics (tents, awnings, rain gear etc) | ||||||

| rayon (cupro) | Degrades in strong alkalis, acids and undiluted bleaches. Resistant to dry cleaning solvents | circular cross section with no striations | sheer fabrics and netting; lightbulb filaments | |||||||

| rayon (viscose) | Degrades in strong alkalis, acids and undiluted bleaches. Resistant to dry cleaning solvents | direct | lengthwise striations; early samples have circular cross sections with serrations, later samples may be dog-boned or trilobal | rugs, cotton substitute, nonwoven fabrics, paper (cellophane) | ||||||

| vinal | Resistant to microorganisms, insects, and most chemicals. | fibers are smooth; cross section is round, ben-shaped or u-shaped | raincoats, jackets, umbrellas, tarps, fishnets, awnings. | |||||||

Fiber Burn Tests

| Fiber | Appearance | Odor | Residue |

|---|---|---|---|

| Natural fibers | |||

| Cotton | Burns very fast with a bright yellow flame, similar to paper | burnt paper | burnt ends look bushy |

| Linen | Burns very fast with a bright yellow flame, similar to paper | burnt paper | burnt ends appear melted together |

| Silk | Burns and bubbles faster than wool with a yellow flame | burnt hair (mild) | black, brittle, spherical beads |

| Weighted silk | Does not burn; the fabric will char | burnt hair (faint) | fabric retains shape |

| Wool | Burns slowly; bubbles while burning; easy to put out flame | burnt hair (strong) | black, brittle, irregular beads |

| Synthetic fibers | |||

| Acrylic | Burns readily with smoky flame | acidic | hard ash |

| Aramid | Does not burn | ||

| Cellulose acetate | Burns fast with a yellow flame; may melt and sputter | burnt paper | hard, black beads; similar to silk |

| Modacrylic | Self-extinguishing | ||

| Nylon | Melts first, then ignites and burns rapidly. | burnt plastic | |

| Polyester | Difficult to ignite, self-extinguishing. Burns with shiny, yellow-orange, sooty flame. | sweet | hard ash |

| Polyethylene | Burns with a heavy, sooty, waxy smoke. Softens at 120 C. | ||

| Polypropylene | Burns with a heavy, sooty, waxy smoke. | ||

| Polyurethane | Burns with bright flame and minimal smoke | ||

| Polyvinyl chloride | Burns with green smoky flame, self- extinguishing. | acidic; releases hydrochloric acid | |

| Rayon (regenerated cellulose) | Burns very fast with a bright yellow flame, similar to paper | burnt paper | light, white ash |

| Vinal | Does not burn | ||

Synonyms and Related Terms

synthetic fibers; man-made fiber; manmade fiber; man-made fibre; fibras sintéticas(Esp.)

For easy printing and to download

Properties of Synthetic Fibers

Resources and Citations

- Wikipedia: Synthetic fiber Accessed Oct. 2024

- Hoechst Celanese Corporation, Dictionary of Fiber & Textile Technology (older version called Man-made Fiber and Textile Dictionary, 1965), Hoechst Celanese Corporation, Charlotte NC, 1990

- Rosalie Rosso King, Textile Identification, Conservation, and Preservation, Noyes Publications, Park Ridge, NJ, 1985

- Marjory L. Joseph, Introductory Textile Science, Holt, Rinehart and Winston, Fort Worth, TX, 1986

- J.Gordon Cook, Handbook of Textile Fibres:II Man-made Fibres, Merrow Publishing Co. , Durham, England

- Theodore J. Reinhart, 'Glossary of Terms', Engineered Plastics, ASM International, 1988

- Art and Architecture Thesaurus Online, https://www.getty.edu/research/tools/vocabulary/aat/, J. Paul Getty Trust, Los Angeles, 2000

- Fairchild's Dictionary of Textiles, Phyllis G.Tortora, Robert S. Merkel (eds.), Fairchild Publications, New York City, 7th edition, 1996